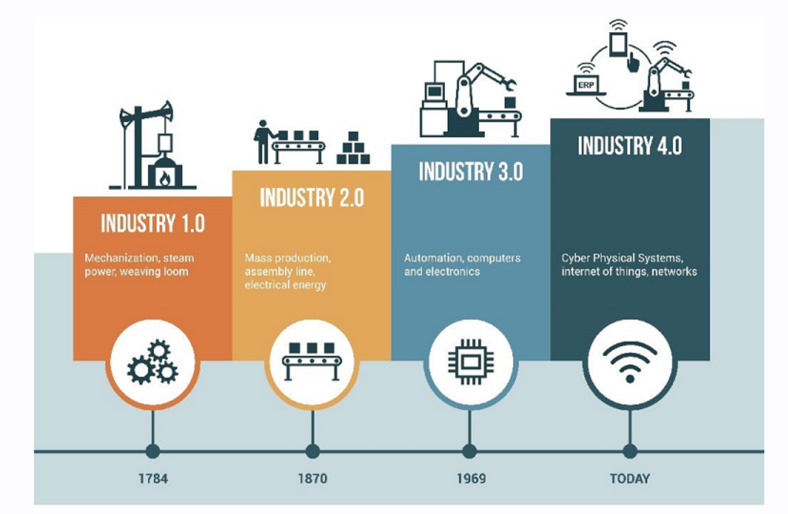

Industry 4.0 in Manufacturing Setups and Marine Vessels

What we do

ONE-STOP SOLUTION FOR COMPLETE FACTORY DATA INTEGRATION

Integration

Single platform for Industry 4.0 (IIOT), Asset Risk Management (ARM), Manufacturing Execution System (MES)

Visualisation

Friendly and interactive user interface, customisable dashboards to visualise useful data and alarms, on desktop, tablets and mobile

End-to-end solution

Turnkey - Supply of Hardware, Software, Design, Engineering, Installation, Commissioning, Testing, Start-up

Failure prediction

Understand the root cause of machine failure modes and write the diagnostics algorithms for failure prediction

Data Acquisition

Select most suitable hardware to acquire Equipment and Process data in real-time

Notification

Advance notification via email and SMS for timely action, Online guidance integrated to troubleshoot equipment breakdown

APPLICATION STACK

iFactoryMonitor

A software platform for data analysis and predictive diagnostics

DATA ACQUIRER

Versatile, flexible, scalable, programmable, Real-time data acquirer

DATA ANALYSER

Capable to write complex rule-based diagnostics algorithms, Multivariate analysis, Integrate different types of databases

UI / UX

Friendly and interactive user interface, Customisable dashboards to visualise useful data and alarms

Access from everywhere

Cloud or local setup as required, Advance notification via email and SMS for timely action, Online guidance integrated to troubleshoot equipment breakdown, Accessible on desktop, tablets and mobile

Projects

.